This Week's Assignment

The assignment for this week was to "make something big" (e.g. a piece of furniture) on a large format CNC machine.

Our lab doesn't have it's own large CNC machine, so we used one at MakLab. I found myself in need of a new desk, so decided to make one for this assignment. Here's the final result:

Desk Design

This was my existing home workbench setup.

That desk on the left is my kitchen table. I told my flatmate I needed to take it from the kitchen "just for a few days". That was three months ago...

I looked for inspiration on the excellent OpenDesk. Having never made a desk before, I was worried about designing something from scratch without having first hand knowledge of the material properties and design principals. To reduce the chances of failure I decided to take one of the existing designs on OpenDesk and modify it to fit my needs.

I settled on the AtFAB One-To-Several Table. I liked the design, and it had additional resources available above and beyond the other desks on OpenDesk. For example, there was the Autoprogettazione app for paramterising the desk. Unfortunately, you can't actually export the results so it's kind of useless...

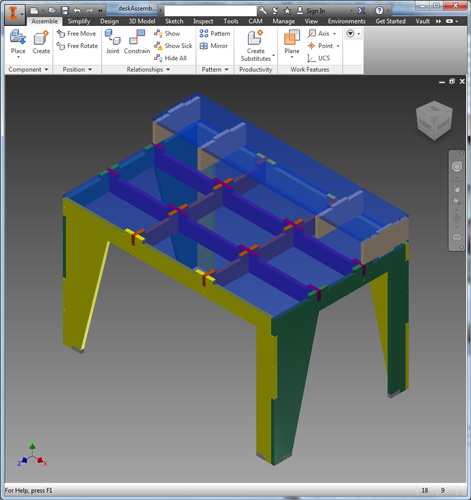

Instead, I remodelled the entire design (parametrically) in Inventor. Here's what I ended up with.

The base desk is pretty much an exact copy of the One-To-Several Table. I then added a shelf to support my PC monitor and speakers. My reasoning was that even if my shelf design failed miserably, I would still be left with a usable desk!

To verify that my Inventor model was accurate I cut a scaled version in 3mm plywood on the laser cutter. My target material for the desk was 18mm ply, so I scaled all the dimensions down by a factor of 6.

The shelf design uses pocket cuts to hold the supports, which I couldn't reproduce on the laser. Overall though the design looked like it was going to work pretty well.

Cutting The Desk

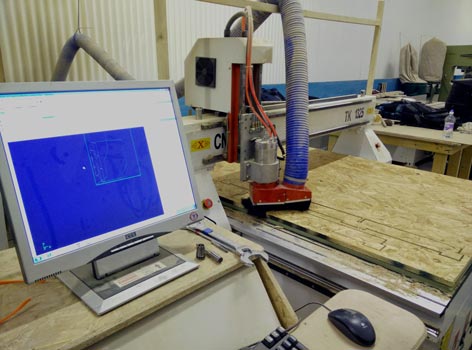

We went down to MakLab to use one of their three large format CNC machines (the lucky sods!). I imported my parts into V-Carve and defined the cut paths based on using a 1/4" upcut bit. Based on settings given by MakLab for the machine, I used the following settings:

- Pass Depth: 4 mm

- Stepover: 40%

- Spindle Speed: 20 krpm

- Feed Rate: 4 m/minute

- Plunge Rate: 2 m/minute

We had a bit of an unfortunate mix up in ordering 18mm plywood (it was going to be delivered too late), so I had to use what MakLab had on hand. That ended up being one sheet of 18mm OSB and one sheet of 18mm MDF. Not the nicest of materials to work with but needs must. I went with the MDF for making the shelf and desk top and used the much rougher OSB for the desk frame and structure.

Cutting the OSB took about 50 minutes, and cutting the MDF (which had some extra parts from my classmate on it too) also took about 50 minutes. We loaded up the car with all of our parts and got them back to FabLab@Strathclyde.

I thought about trying to hide the fact that the table was made of OSB and MDF by painting it but figured it would be hard to get a convincing finish. Instead, I went down the complete opposite route and decided to flaunt the "homemade" look by varnishing everything.

I grew to regret this decision, because it meant a lot of sanding and varnishing. Here's a before and after shot after the first round of sanding:

To get a "good" finish on the OSB I had to do one sanding session with a powered sander, then a layer of varnish, followed by hand sanding and another coat of varnish and then another hand sand and varnish and then a final hand sand! Overall it probably took me about two full days to get an OK finish on the OSB. If I charged for my time, I would now own one of the cheapest looking expensive desks in the world.

With the help of a persuasion device (i.e. a hammer), I assembled the desk and used a drill to make the pilot holes for screwing everything together. Here's the desk in it's new home.

Get The Files

My full file set is way too big for the archive, so I'm only uploading a subset of files here.

Comments

comments powered by Disqus